Elevate Performance: Necessary Tips for Preserving Undercarriage Parts Efficiency

Elevate Performance: Necessary Tips for Preserving Undercarriage Parts Efficiency

Blog Article

Crucial Overview to Undercarriage Components for Heavy Equipment

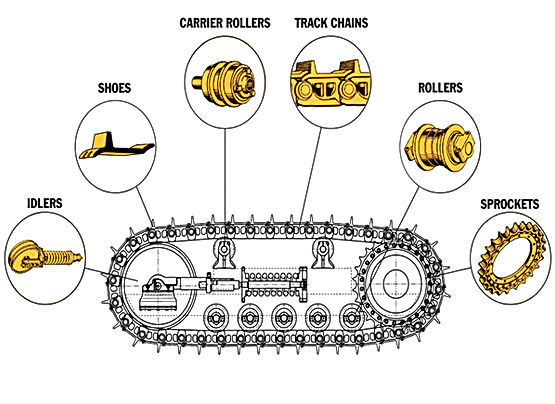

When it comes to heavy devices, the undercarriage plays a vital role in making certain smooth and reliable procedures. From track chains to rollers and idlers, each element adds to the overall performance of the tools.

Significance of Undercarriage Components

Comprehending the essential role that undercarriage components play in the efficiency and durability of heavy devices is critical for reliable maintenance and procedure - undercarriage parts. The undercarriage components develop the foundation on which the entire maker runs, sustaining the weight of the equipment, supplying security, and absorbing shock tons throughout operation. A well-kept undercarriage not just ensures smooth operation but also adds dramatically to decreasing downtime and fixing costs

The undercarriage consists of numerous necessary parts such as track chains, track footwear, gears, idlers, rollers, and track frames. The track chains and track footwear help in giving traction and assistance, while the gears and idlers assist in driving the tracks efficiently.

Types of Track Chains

Track chains are important elements of heavy devices undercarriages, giving the needed grip and assistance for efficient operation. There are mainly two types of track chains utilized in hefty devices: secured and oiled track chains (SALT) and completely dry track chains.

Function of Rollers and Idlers

Rollers and idlers play an important role in sustaining and directing the track chains of hefty equipment undercarriages, adding to the general security and efficiency of the equipment. Rollers are developed to sustain the weight of the equipment and give a smooth surface for the track chain to relocate along. They help disperse the weight evenly, reducing excessive wear on the track chain and making certain appropriate grip. Idlers, on the other hand, guide the track chain and aid maintain correct tension throughout the undercarriage system. By assisting the track chain in a controlled fashion, idlers avoid too much side-to-side movement, minimizing the threat of derailment and unequal wear.

Together, idlers and rollers operate in harmony to guarantee that the track chain stays in area, even on rough terrain, boosting the tools's efficiency and longevity. Proper maintenance and routine examination of rollers and idlers are vital to protect against early wear and potential malfunctions, inevitably making best use of the performance and lifespan of heavy devices undercarriages.

Comprehending Sprockets

One critical element of sprockets is making certain appropriate alignment and tension to stop premature wear and damages. Misaligned sprockets can trigger uneven endure the track chain, bring about decreased performance and potential safety and security dangers. Normal upkeep and inspection of gears are vital to identify any kind of indicators of wear or misalignment promptly.

Furthermore, gears are available in numerous sizes and tooth setups, relying on the particular hefty tools and its intended usage. Correct selection of sprockets based you can try these out upon the tools's specifications is crucial to make certain optimal performance and long life of the undercarriage system. Recognizing the role of sprockets and their upkeep needs is essential for making the most of the effectiveness and life expectancy of hefty equipment undercarriages.

Maintenance Tips for Durability

To make certain the prolonged sturdiness and optimum capability of hefty equipment undercarriages, persistent maintenance methods are necessary. Regularly examining undercarriage parts such as track shoes, rollers, idlers, and sprockets for deterioration is important. Change any kind of used or broken elements without delay to avoid further damage to the undercarriage system. Appropriate track tension modification is likewise crucial for minimizing early endure undercarriage parts. Over-tensioning can cause boosted anxiety on the parts, while under-tensioning can create track slippage and increased wear. In addition, maintaining the undercarriage tidy from particles accumulation, mud, and various other contaminants can aid protect against corrosion and expand the life-span of the components. Oiling the undercarriage parts at suggested periods will certainly likewise decrease friction and wear. Scheduling normal maintenance checks with experienced professionals can determine possible problems early on and address them prior to they rise, inevitably making the most of the longevity of hefty devices undercarriages. undercarriage parts.

Verdict

In final thought, undercarriage parts are necessary elements for hefty devices, playing vital duties in preserving stability and performance. Appropriate care and attention to undercarriage parts are key to making the most of equipment lifespan and productivity.

The undercarriage is composed of numerous necessary components such as track chains, track shoes, sprockets, idlers, rollers, and track structures. The track chains and track shoes aid in giving grip and support, while the idlers and gears aid in driving the tracks efficiently (undercarriage parts). There are largely 2 types look at this now of track chains used in hefty tools: sealed and oiled track chains (SALT) and dry track chains. Appropriate selection and maintenance of track chains are essential to ensure the general performance and durability of heavy devices undercarriages

Sprockets are indispensable parts of heavy equipment undercarriages, liable for transferring power from the equipment to the track chain.

Report this page